Engine Valves

HSD has been manufacturing custom engine valves since the early 1980’s.

Machined up from 214n one piece stainless steel forgings ranging in stem sizes from 6mm through to 7/16 in diameter.

Our CNC. Machining Centre enables us to manufacture engine valves to your exact requirements ie: margin width, profile and under head dishing. Each valve has its own special characteristics, for example, the air flow across the back of a valve can vary greatly depending on its shape, either enhancing or detracting in the overall performance of a cylinder head. For this reason we have a vast range of valve profiles to choose from which allows us to supply a valve combination which will best suit your needs.

Our valves usually have an undercut stem, they are swirl polished to eliminate fatigue points due to machining processes and they are tufftrided to enhance wear resistance. However, we will manufacture any engine valve to conform to your desires.

Download the Custom Valve Design Spec Sheet

General Engineering

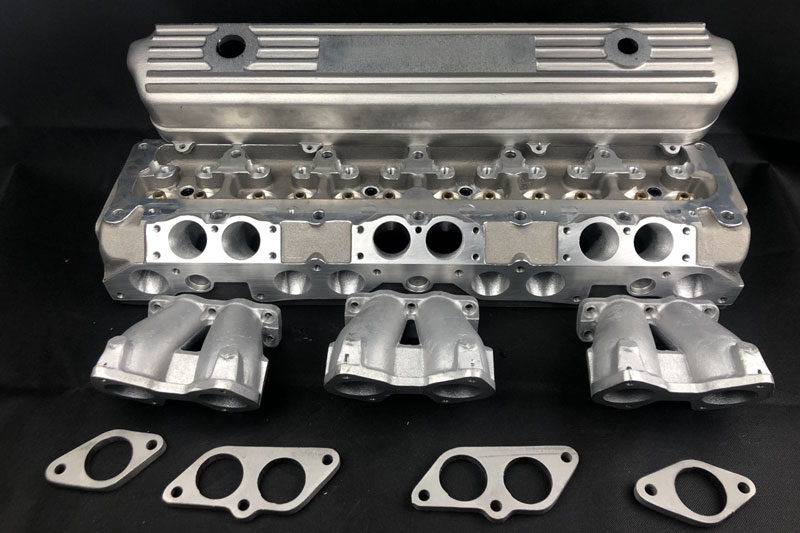

HSD has for many years had a history of being capable of producing a wide and varied range of specialty products in the field of general engineering, such as prefabricated manifolding cold air boxes, specialised bracketry and mounting plates, just to name a few. Now with our CNC. milling and turning centres we are able to machine specialised pulley configurations and alloy billet components to suit your needs. We also manufacture valve guides and camshaft bucket lifter guides, etc.

Because of our versatility and willingness to take on unusual tasks and small production runs we fit into a market area that may be able to assist you in many diverse ways. There is almost nothing that we are unable to produce in a high quality and competitive manner. We very much look forward in being able to assist you in creating and supplying you with the products that your special project may require.

Engine Builds

Our engine building facility adopts the same philosophy that our cylinder head development aspires to, you only get what you pay for but; we insist that HSD products must be to the standard that we would be prepared to accept if we were the paying customer. Therefore we build as much quality as your budget will allow into every engine build we do whether it be competition, hot road use or restoration.

We take pride in delivering an engine package that not only performs to your expectations but at the same time must meet your standards of appearance, together with our experience in cylinder head development and our knowledge of camshaft selection we are able to recommend and provide an engine combination that will enhance your vehicles value and performance requirements.

Cylinder Heads

- Reconditioning cylinder heads: ALL TYPES OF HEADS 4, 6, 8, bike, jetski boat. Multi Angle Seat Machining, Head and manifold Surfacing, Inserting inc. L.P.G., Head straightening, Pressure testing, Crack testing, sand blast cleaning, Helicoils, Aluminium welding.

- Porting and Port matching: Is process of modifying the intake and exhaust ports of an internal combustion engine to improve the quality and quantity of the air flow.

- Flow bench testing:is a significantly important process in the development of cylinder head modification, however it must be stressed that a flow bench is only a measuring tool and it is only as good as the person operating it. Not every cylinder head needs to be flowed but if you the customer requires or desired a specific HP. capability out of your cylinder head or heads then flow bench testing is highly recommended.

Our bench is operated at 25 inches of H20 and in most applications we are able to predict with a great deal of accuracy the amount of HP. that your cylinder head package might achieve.

HSD’s Heads

We are currently casting and manufacturing 3 new cylinder heads and are re-manufacturing classics

- XU1 Torana head

For more information or to book your high performance vehicle in at our modern workshop, please give us a call today!

Historic Cars

Our involvement in historic cars and historic race cars, their development and restoration is not just an area that we are simply interested in, it is more of a passion, we have been involved in the preparation and restoration of vehicles such as the Rothman’s Mattich Special owned by Nigel Tate and Bob Jane’s Repco Brabham powered Sports 400. We have been pioneers in developing Torana XU1cylinder head packages in conjunction with Ian Tate and other reputable engine builders such as Trevor Simkin and Wayne Mahnken, that consistently and reliably produce over 300 HP, we developed and prepared the cylinder head that was fitted to the FX Holden that Peter Brock raced at the Goodwood festival.

We specialize in many pre war vehicles such as over head cam MG’s, early and current day Porches, Ferraris, Aston Martins, Jaguars and Repco Hi power Grey motor Holdens only to name a few, the list goes on, it could probably be best characterized by saying that anything nobody else is willing or prepared to tackle, we will. We enjoy and welcome almost any challenge with enthusiasm and dedication, we look forward to your enquiries and trust that we may be able to assist you in the restoration and or development of your hobby or passion.

Diagnostics

Here at Head Stud Development, we use the latest in vehicle diagnostic technology to diagnose and repair the most complex of cylinder head issues.

With a reputation for excellence in everything we do, our team of mechanical experts will never cut corners. This ensures our customers and their high performance vehicles receive the best care that modern diagnostic tools and automotive knowledge can deliver.

For more information regarding our range of diagnostic services, please give our friendly team a call today!

Other Services

Here at Head Stud Development, we can offer servicing, maintaining and tuning up our Aussie and American icons from the 1950’s- 70’s

For more information regarding our range of diagnostic services, please give our friendly team a call today!